Transformer losses: why they are important and how to minimize them

Every transformer, even the most efficient, loses some energy in the form of heat. These transformer losses, small as they may seem, accumulate in the long run and lead to higher financial costs and a negative impact on the environment. Let us therefore look together at the different types of losses, their causes, and especially the methods of minimising them.

Transformer losses have a direct impact on the efficiency and cost of operation

Although transformers are designed to minimize losses, they cannot be completely avoided. However, several types of losses are known:

- No-load losses occur in the iron core of the transformer. We therefore call them iron losses. They reduce the efficiency of the equipment even in the idle state. They are load-independent losses. Their minimization therefore plays a very important role in long term grid connection and in transformers that operate in standby mode for long periods. Long-term operation with high no-load losses can lead to significant financial losses.

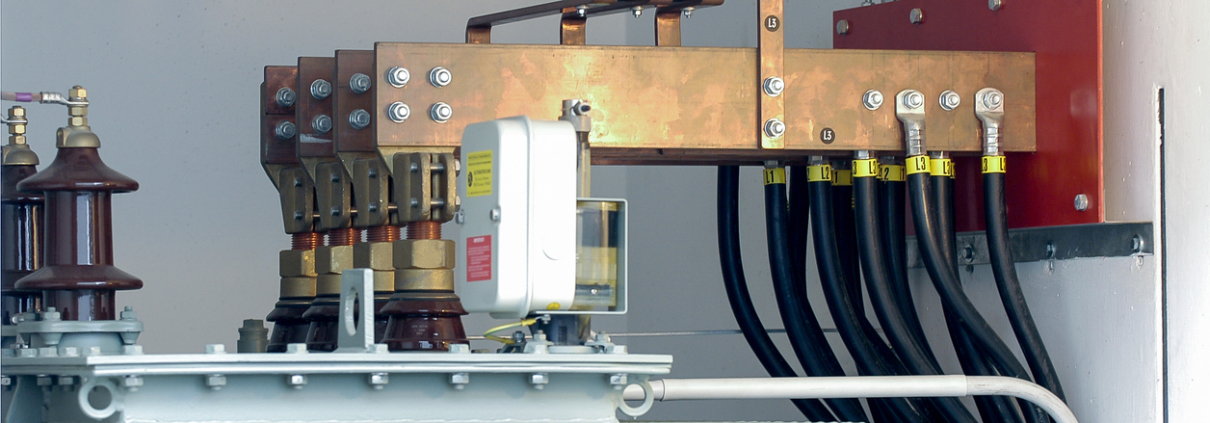

- Short-circuit losses ( or winding losses) are due to the resistance of the transformer windings through which current flows. These losses are directly dependent on the load on the equipment – the higher the load, the higher the losses. Therefore, it is extremely important to design the transformer with a good quality conductor.

Minimise transformer losses: increase efficiency and reduce operating costs

There are various techniques and technological solutions aimed at reducing dead, short and no-load losses:

- Optimization of core design: the core plays a significant role in the generation of idle losses. However, high quality materials (silicon steel) can reduce losses by reducing core losses and improving the overall efficiency of the device. It is also important to reduce eddy currents, which can be achieved by laminating the core. The core consists of thin sheets separated by an insulating layer.

- Winding design optimization: losses due to conductor resistance can be reduced by using lower resistance materials. Optimisation of the winding geometry is also important. Proper winding layout can improve the efficiency of the transformer.

- Use of modern technology: modern technology can also solve the problem of a transformer connected to the grid for a long time. There are materials with lower hysteresis and eddy losses and also modern control systems that optimize the load on the equipment in real time.

Transformer losses and their impact on operating costs and the environment

The presence of losses directly reduces the efficiency of the device. Losses in the iron (idle) reduce efficiency even at low load or even in standby mode. Losses in the windings (shorted) increase with load. Higher transformer efficiency means lower losses, and this translates into lower power consumption and more stable operation. Conversely, higher losses in the transformer increase power consumption. In addition, they can increase both cooling and maintenance costs. This is because losses are converted into heat that needs to be dissipated, and this requires an efficient cooling system. Prolonged exposure to higher losses can reduce service life, which in turn leads to more frequent repairs.

Energy losses in transformers also indirectly affect the environment. The amount of energy consumed has an impact on greenhouse gas emissions. The environmental burden is also increased by the more frequent disposal of transformers with shorter lifetimes due to high losses.

Investing in efficient transformers will bring significant long-term benefits

Although the initial cost of modern and low-loss transformers may be higher, ultimately minimizing losses leads to significant energy savings, reduced operating costs, and extended equipment life. Higher upfront costs are also recovered after just a few years in the form of lower utility bills and reduced operating expenses.

Minimising losses leads to long-term energy and cost savings. In continuous operation, energy savings can represent significant financial benefits. The benefits of quality transformers include fewer faults and downtime, which means lower repair and equipment replacement costs. More reliable operation with less risk of unexpected failures is just one of the significant benefits of extended lifetime.

Ak hľadáte efektívne a spoľahlivé riešenia, neváhajte kontaktovať spoločnosť BEZ TRANSFORMÁTORY. Pomôžeme vám vybrať najvhodnejšie zariadenie, pričom zohľadníme vaše špecifické potreby. Poskytneme vám aj komplexné poradenstvo v oblasti minimalizácie strát a optimalizácie energetickej účinnosti.

Leave a Reply

Want to join the discussion?Feel free to contribute!