Transformers in photovoltaics: choosing the right transformer for maximum efficiency of a photovoltaic power plant

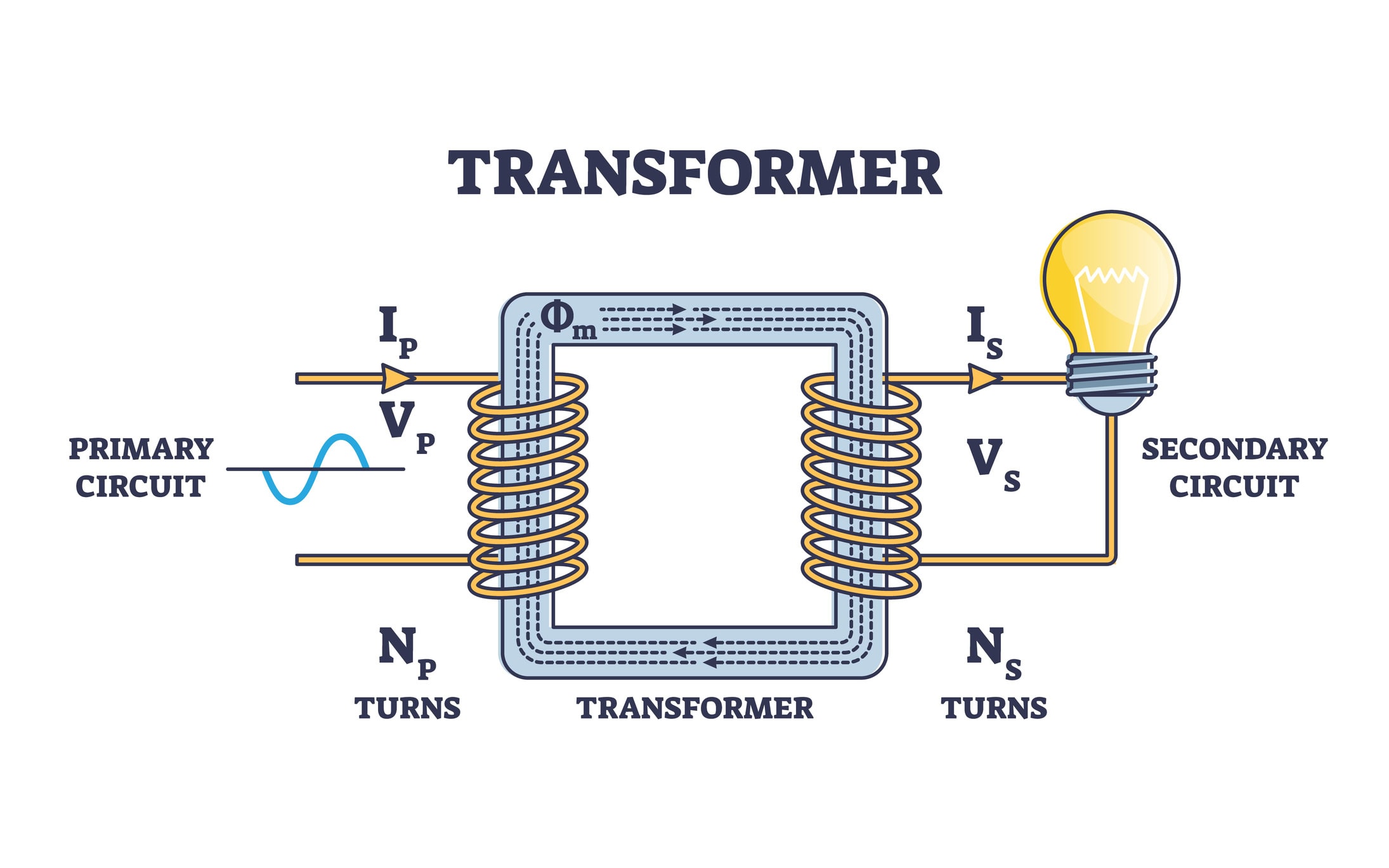

Discussions of green energy often focus on photovoltaic panels, which convert sunlight into electricity, and inverters, which transform direct current into alternating current. While these components are crucial, there is another and often overlooked link in the chain between the PV array and our homes or industrial plants: the transformer. But transformers in PV are not limited to raising the voltage.

The role of transformers in photovoltaic power plants

Photovoltaic systems, whatever their size, have a fundamental challenge: the energy they generate must be adapted to meet the stringent requirements of the electricity grid.

Increasing tension

Photovoltaic panels produce direct current (DC), which the inverter then converts to alternating current (AC). However, this AC current is generated at a relatively low voltage. While this would be sufficient for normal domestic use, it is inefficient and uneconomical for transmission over medium and long distances to distribution points. Therefore, a transformer comes into play. It receives AC current from inverters and its main task is to radically increase the voltage to grid level (e.g. 22 kV, 35 kV, or up to 110 kV for large parks). Without this step, there would be huge energy losses. This is because higher voltages allow power to be transmitted at a much lower amperage, thus minimising losses in the lines.

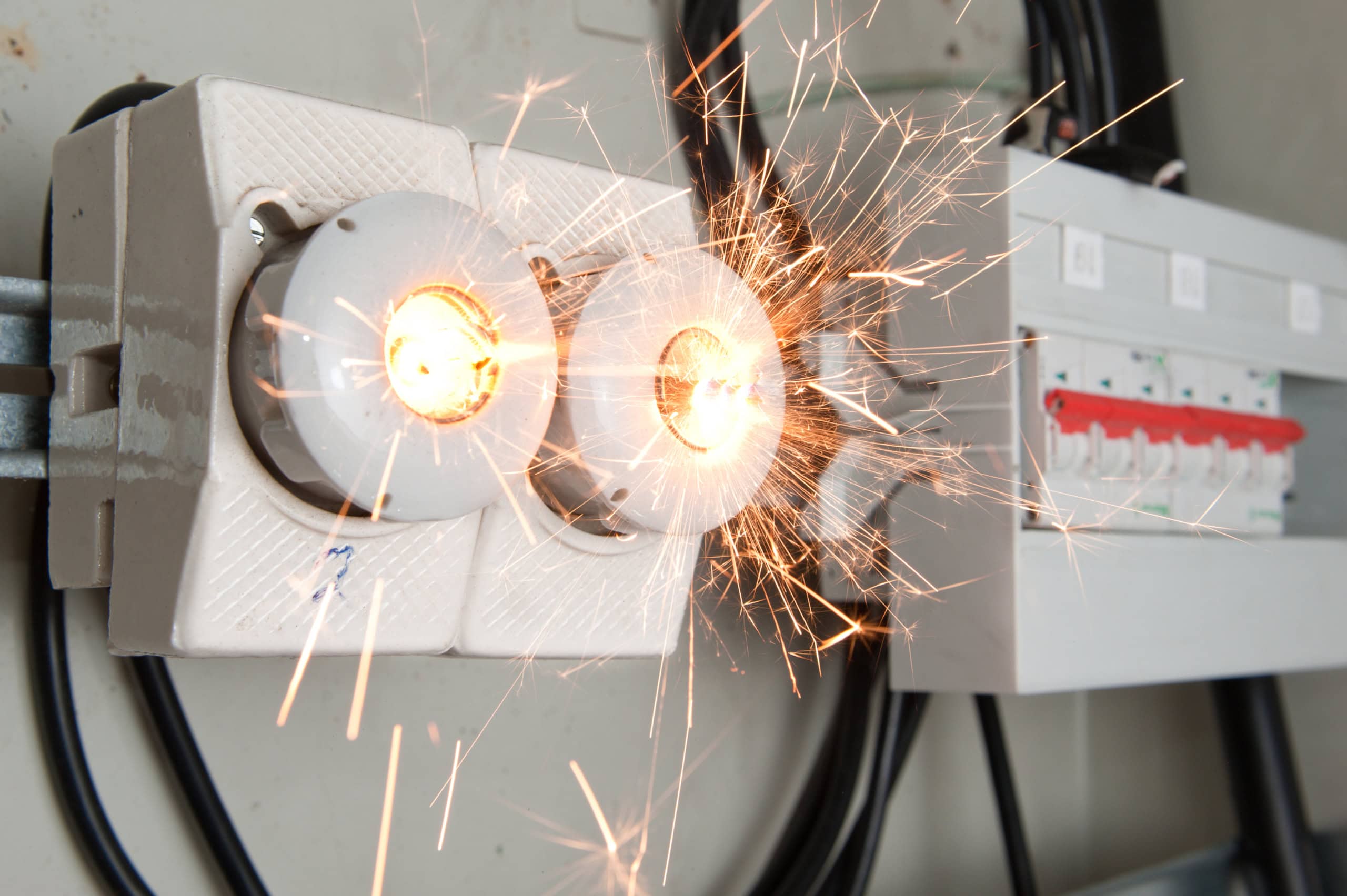

Insulation and system safety

The transformer also performs a safety function. It provides galvanic isolation of the photovoltaic system from the distribution network. This decoupling protects the expensive and sensitive inverters from surges, surges and faults that can occur on the grid, while ensuring that faults in the solar park do not critically affect the stability of the utility grid.

Typology of transformers in photovoltaic systems

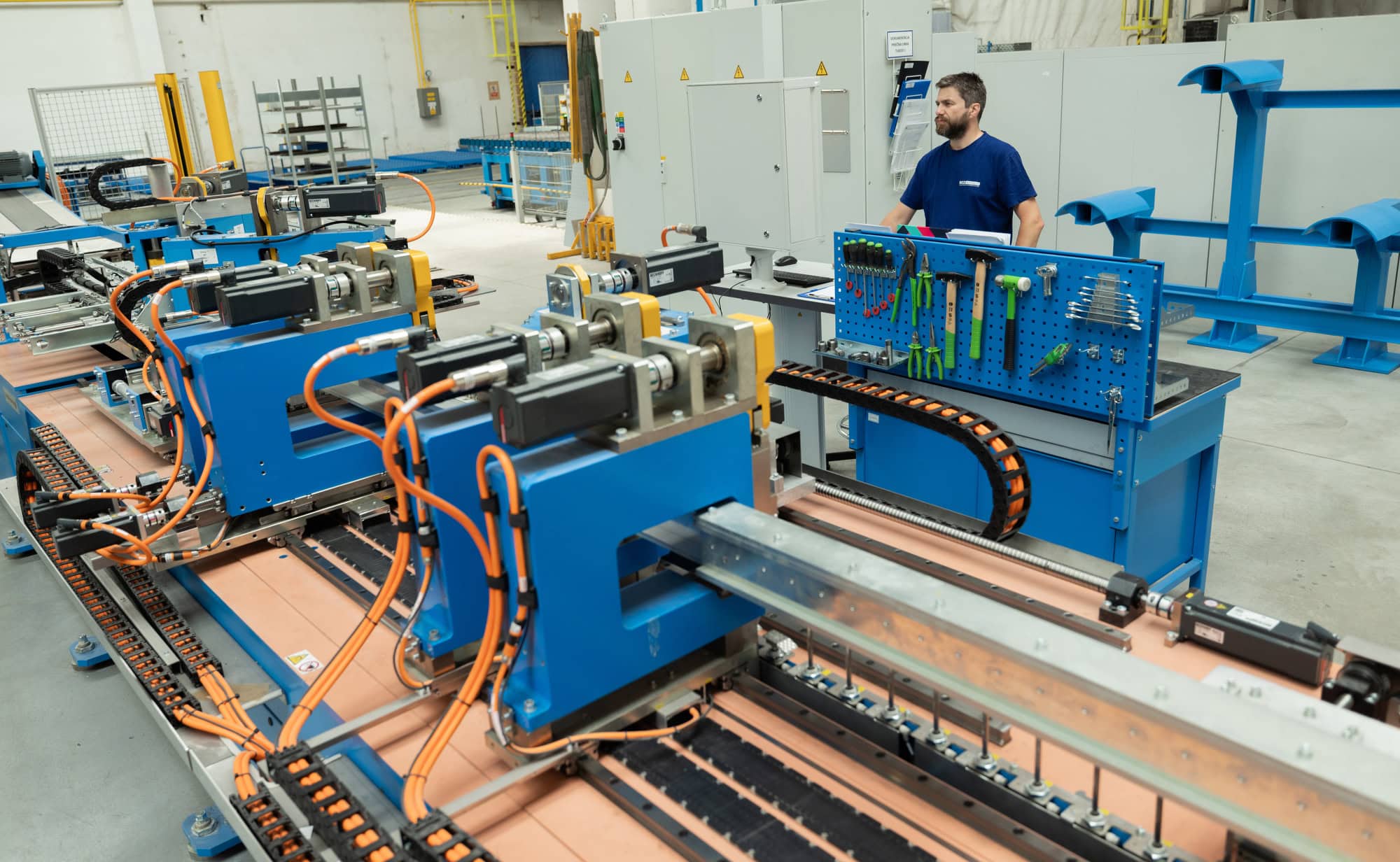

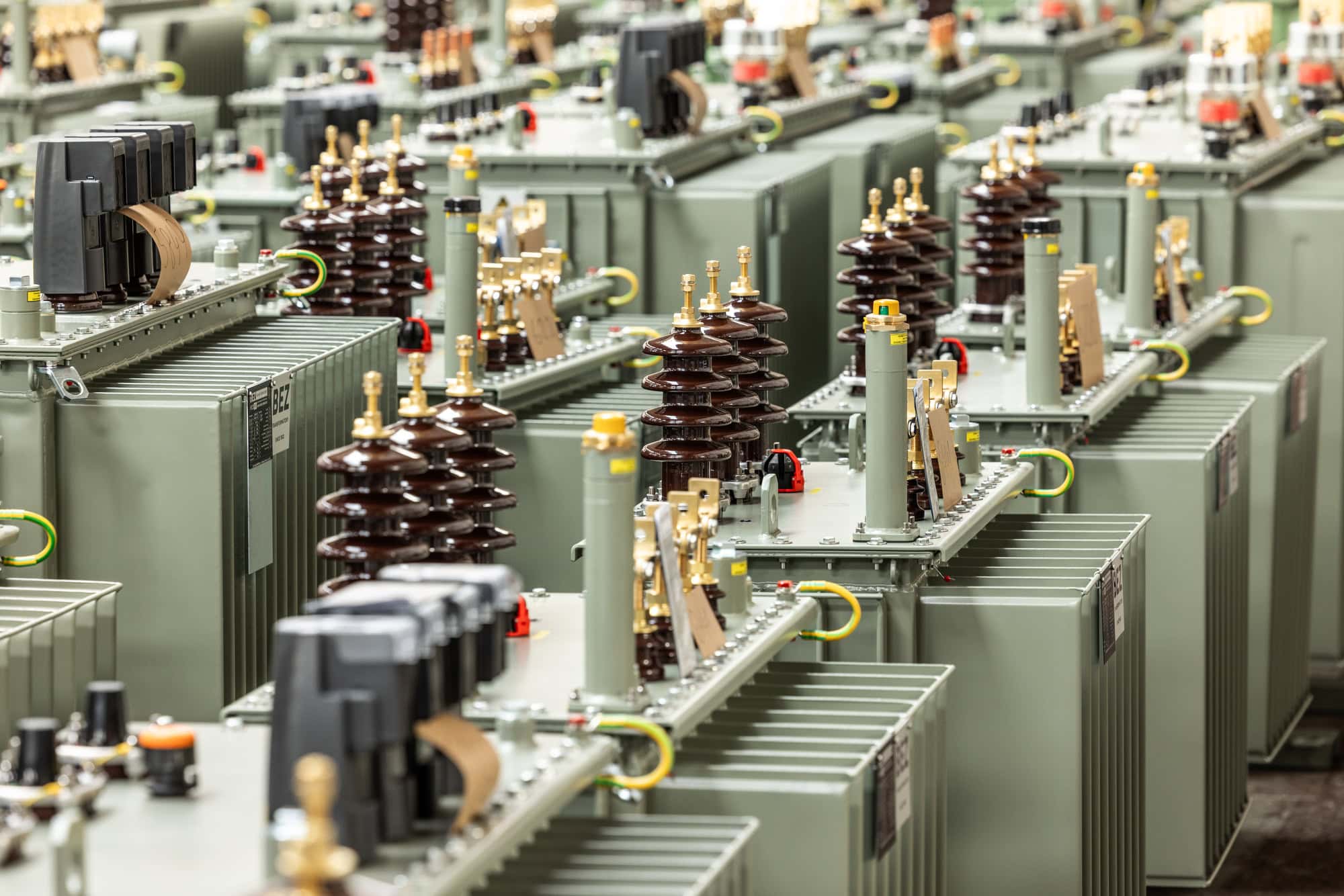

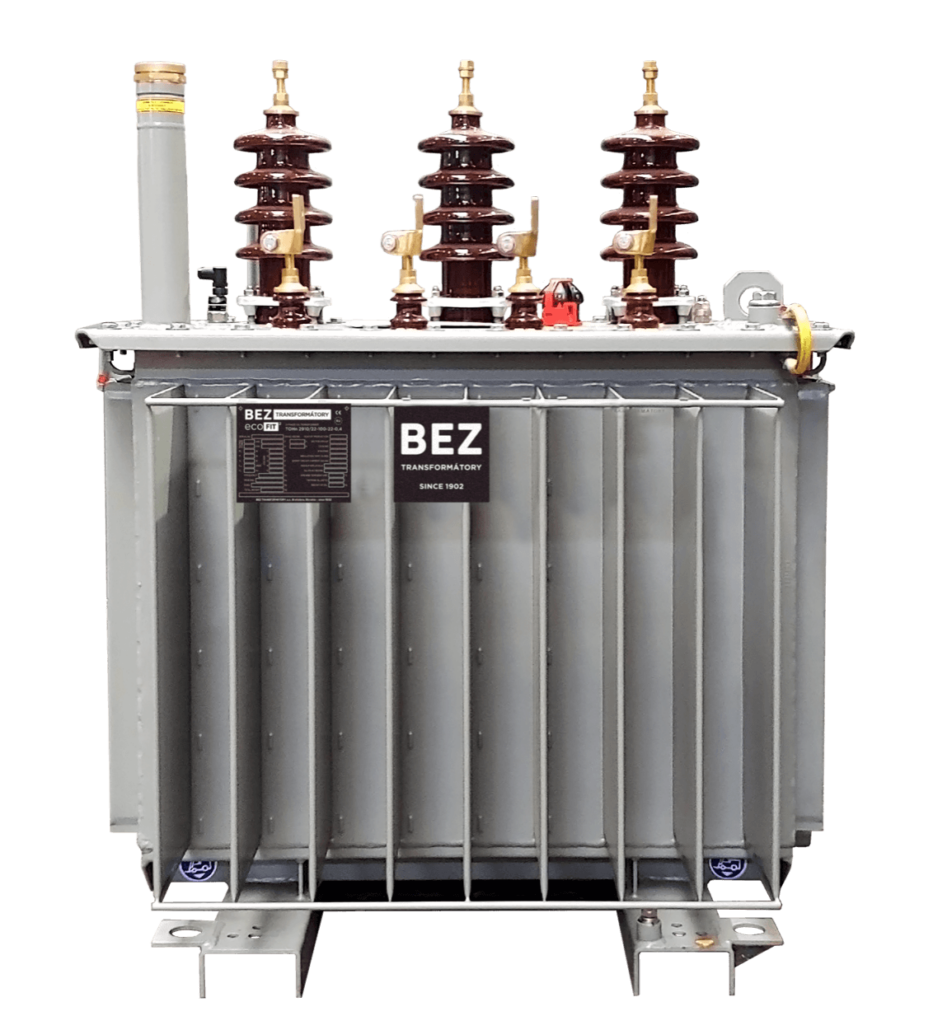

BEZ TRANSFORMÁTORY offers two main types of transformers for photovoltaic parks: oil-immersed and dry-type transformers.

Oil Transformers for Renewable Energy

Oil-cooled transformers are cooled by mineral oil and are the most widely used type in the long term, particularly suitable for outdoor PV park environments where they can withstand adverse weather conditions. Thanks to oil cooling, they can dissipate heat efficiently even under higher loads and offer excellent reliability and extended service life.

Dry-type transformers for renewable energies

Dry-type transformers do not use liquid dielectric, but are cooled by air. They are ideal for indoor and container stations where there are increased demands on fire safety, for example in close proximity to inverters or in densely built-up areas. They are more environmentally friendly, require less maintenance and eliminate the risk of oil leaks.

Impact of transformers on the efficiency and stability of power transmission

The quality of the transformer directly determines the economic success and technical reliability of the entire solar project.

Efficiency and loss minimisation

As we have already mentioned, loss minimisation is a key factor. This is because by increasing the voltage, the current drops, which dramatically reduces the heat loss. Transformers with low intrinsic losses maximize the amount of energy produced that actually reaches the consumer. Thanks to their robust design and life expectancy in excess of 30 years, transformers guarantee a long-term return on investment and reliable operation of the PV park in a variety of climatic and operating conditions. The investment in a transformer with low no-load and short-circuit losses will thus pay for itself many times over during the long lifetime of the project.

Network stability and quality control

Photovoltaics, although a clean source, can present challenges in the form of voltage fluctuations and THD harmonic distortion generated by inverters. Therefore, advanced transformers have systems that allow smooth and automatic voltage regulation, thus maintaining grid stability even with rapid changes in sunshine. In addition, the transformer helps to dampen and filter harmonic currents. This ensures that the energy supplied to the distribution system is clean and meets all standards.

The challenge of the future

As PV expands and integrates into smart grids and battery storage, the demands on transformers will only increase. Their quality design, ability to handle fluctuating loads and minimize losses are essential for a successful and sustainable transition to green energy.

If you are currently designing or optimizing your PV park and are looking for a customized solution that guarantees low losses and long lifetime, contact us. Our technical specialists will be happy to help you with your selection.