Transformer voltage transformer: key role and practical application

Without transformers, electricity could not travel efficiently and safely from the power station to your socket, nor would most industrial machinery work. But all functionality depends on one key principle. It is voltage conversion.

How transformers change voltage level

A transformer is essentially a static device that transfers electrical energy from one circuit to another without direct electrical contact, using a magnetic field. The principle of electromagnetic induction is the basis for voltage transfer in a transformer , discovered by Michael Faraday. When an alternating current passes through the primary winding, it creates a constantly changing magnetic field in the core. This changing field passes through the secondary winding and induces a voltage in it. What the output voltage level will be depends entirely on the ratio of the number of turns of the primary and secondary windings. This relationship defines the key parameter of the transformer: the transformation ratio.

Voltage units and conversion of voltage units

When discussing voltage conversion, we cannot avoid the fundamental physical quantity: electrical voltage. The basic unit of electrical voltage in a system is the volt, named after the Italian physicist Alessandro Volta. The conversion or transformation of voltage units is, of course, necessary for the precise design and operation of networks. When we need to determine what voltage a transformer will handle, we always work in consistent units: volts, millivolts, kilovolts or megavolts.

From mains to USB charger

The role of transformers is divided into two main categories: strategic (in the power sector) and local (in industry and households). At BEZ TRANSFORMÁTORY, we specialize in distribution transformers, which are critical in the transition between the grid and the end consumer.

The key reason for voltage transfer is to minimize transmission losses. The higher the voltage, the lower the current, and the lower the heat losses on the lines. Boosting transformers operate in the vicinity of power plants . Electricity is generated at lower voltages (e.g. 10-25 kV). Step-up transformers immediately convert it to very high transmission voltages (e.g. 110 kV, 220 kV, 400 kV) for efficient long-distance transmission. As the power approaches populated areas,

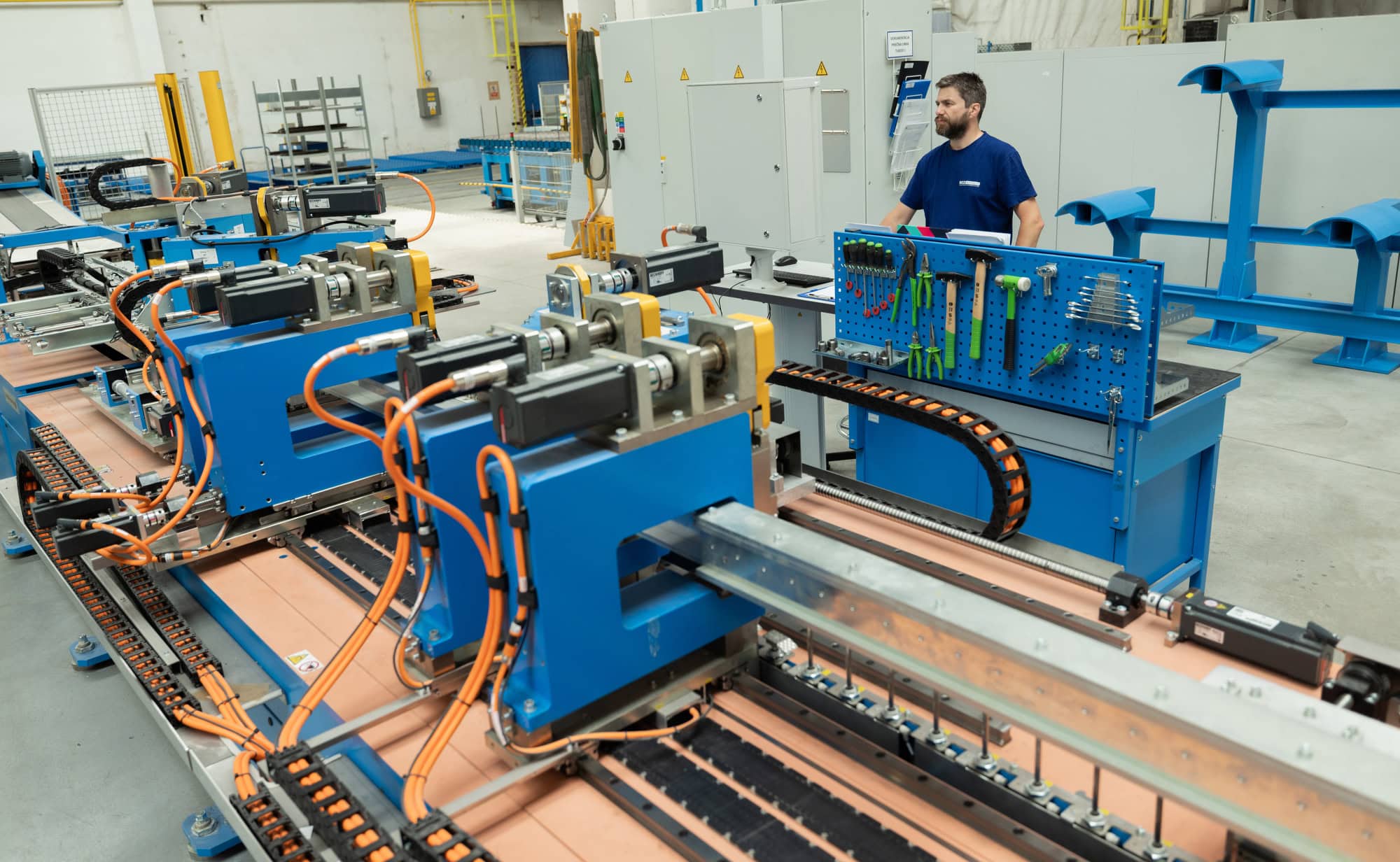

In the industrial environment, voltage conversion is important for powering specific machines and improving safety. Finally, also in solar parks and wind turbines, transformers raise the generated voltage to grid level so that it can be distributed efficiently.

Transformers are part of your life all the time. For example, you will find a distribution transformer in front of your house that reduces the voltage from 22 kV to the standard 230 V for your home. Most of the home voltage transfer is then provided by small adaptors (which contain miniature transformers or electronic switching power supplies). Almost every device that does not run directly on 230 V (mobile phone chargers, laptop chargers, LED lighting) needs a step-down transformer or electronic substitute to safely reduce the voltage (e.g. from 230 V to 5 V for USB or 12 V for lighting).

Voltage transfer is more than just a technical operation

It is the pillar on which modern electricity infrastructure stands. It allows us to transmit electricity with minimal losses while delivering it safely to every device, from a huge production line to the smallest LED bulb.

As the only manufacturer of distribution transformers in Slovakia with more than 120 years of tradition, BEZ TRANSFORMÁTORY ensures that this critical voltage transfer takes place reliably and efficiently throughout the distribution network, making it a key link in the stability of the energy infrastructure.