How to ensure the highest efficiency of the transformer

Today, every kilowatt hour is important. Transformer efficiency therefore plays a key role not only in terms of cost savings, but also in the context of sustainability and environmental responsibility. Even small inefficiencies in operation can translate into a significant loss of energy and money in the long run. In addition, there are now increasingly stringent demands on manufacturers and operators. So the question is how to ensure the highest transformer efficiency?

What does transformer efficiency mean?

When we talk about the efficiency of a transformer, we mean the ratio between the electrical power entering it and the power leaving it. In other words, it is about how much power passes through the transformer without losses. The ideal would be 100%, of course, but in practice transformers always experience some losses. For small transformers this may be a negligible amount of energy, but for large units in industrial plants or distribution networks it is a significant factor.

Why is efficiency never 100%?

Because the laws of physics apply inexorably. For every time energy is transferred, some of it is converted into heat or some other form that cannot be used. Ideally, the efficiency of a transformer should be in the range of 98 to 99.7 %, depending on the type, power and operating conditions. Modern transformers are therefore designed to minimise losses.

Factors influencing efficiency

For a transformer to work as efficiently as possible, it is not enough to have a good design. The materials used, manufacturing technology and correct operation also play an important role.

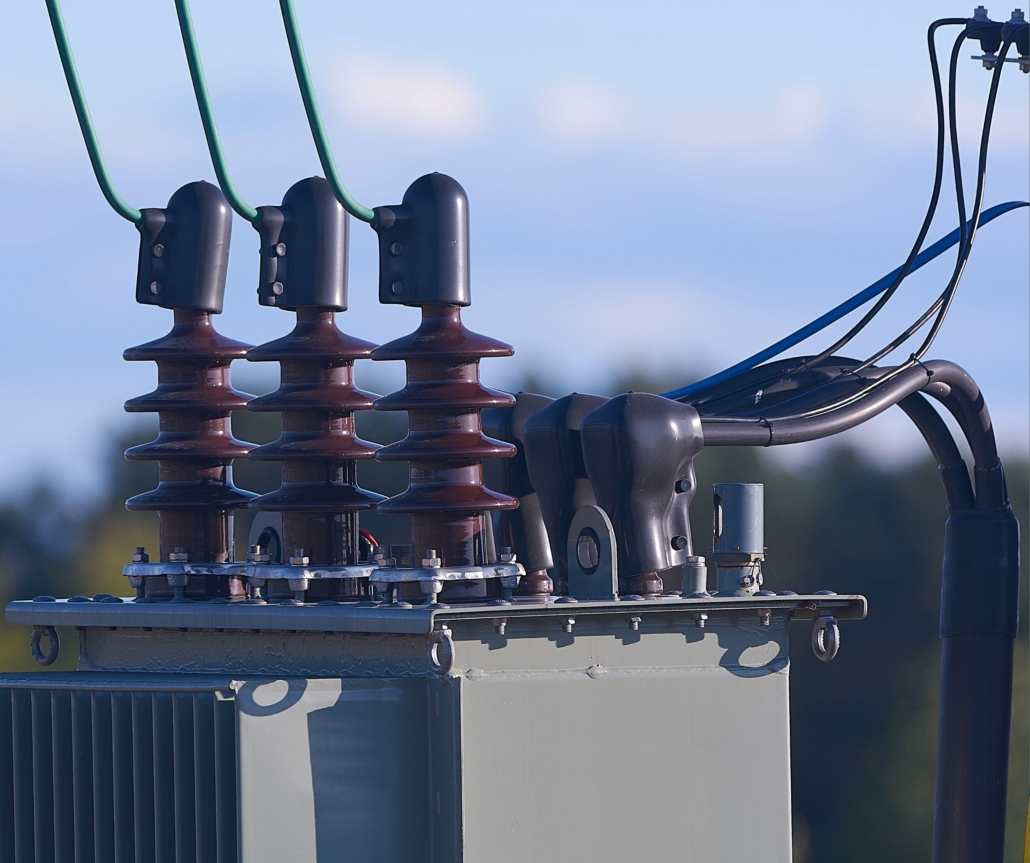

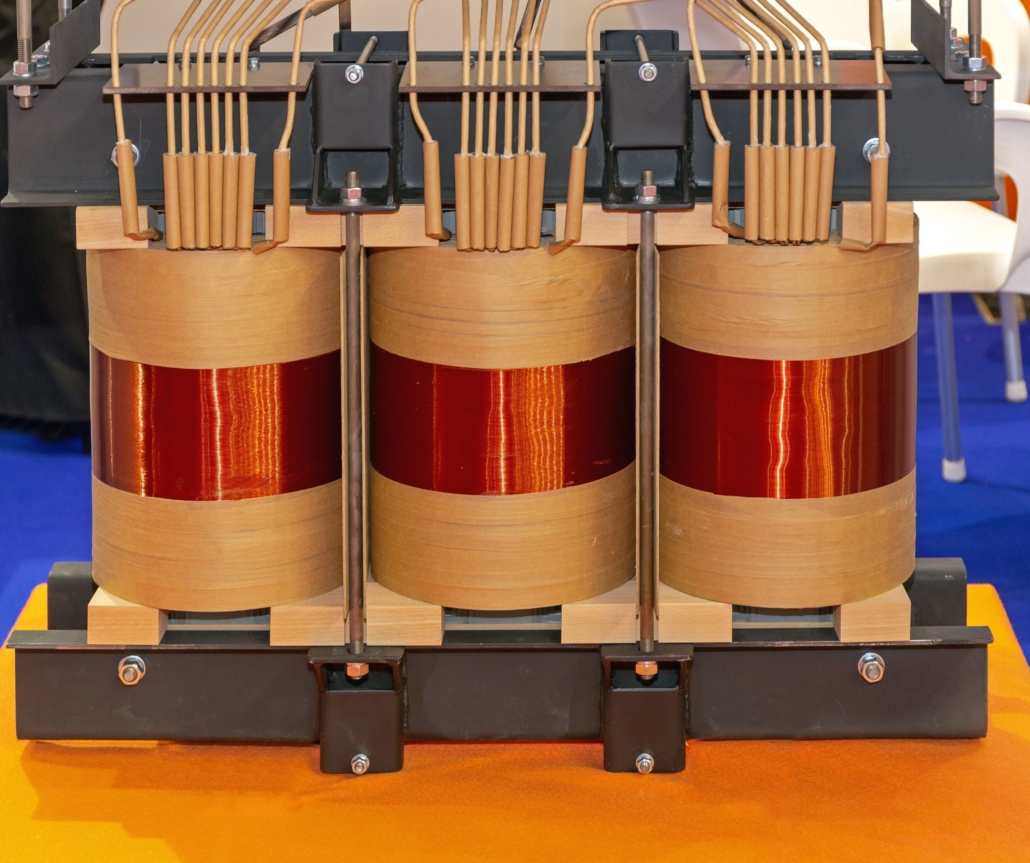

- The heart of the whole device is the transformer core. The losses that occur in it can be significantly influenced by choosing the right material.

- Another source of loss is the windings, i.e. the coils through which the electric current flows. Here the material, shape and arrangement of the windings and the cross-section of the conductor play a role.

- The losses in the transformer are largely converted to heat. If it is not dissipated properly, it increases the temperature of the components, leads to reduced efficiency and faster aging of insulating materials. The transformer cooling system can be optimized by varying the type of finning, oil flow or fan placement.

- The transformer should exactly match the planned operation. An oversized one may have unnecessarily high iron losses at low load. Conversely, an undersized one will suffer from increased heating and faster wear.

The right combination of these factors can determine whether a transformer will be a reliable helper or a source of unexpected expenses.

Proper operation and maintenance

Even the best designed and manufactured transformer can lose efficiency if not operated properly. Long-term efficiency is the result not only of quality design, but also of responsible operation.

- The transformer requires regular technical care. Basic activities include checking the insulating oil, measuring the temperature and load, removing dust and dirt, and checking the mechanical connections and insulation. Properly performed maintenance can extend the life of the equipment by years.

- The transformer should be operated in the range for which it was designed. Continuous overloading leads to temperature rise, increased losses and faster aging of materials. However, prolonged significant low loads cause unnecessary iron losses and inefficient operation.

- The efficiency of the transformer also decreases due to hidden faults or substandard conditions. Excessive moisture in the oil or windings, weak contacts or corroded connections, vibration and noise, or contamination around cooling parts can be problems. However, preventive diagnostics and early intervention are cheaper and more effective than dealing with the consequences.

At BEZ transformátory, we believe that service and support after delivery are just as important as the production itself. We are a reliable partner who can help you not only with the selection of equipment, but also with its efficient operation throughout its lifetime.

Highest efficiency is not an accident, but the result of the right decisions

Losses in the core and in the winding have the greatest effect on efficiency. However, they can be significantly reduced by quality design and materials. Cooling, proper sizing and manufacturing technology have a major impact on energy losses. Efficient operation and regular maintenance are essential for long-term reliability and high efficiency. However, an investment in a high quality, high efficiency transformer pays for itself in lower operating costs over its lifetime.

V BEZ TRANSFORMÁTORY we combine more than 100 years of experience with the latest technology and an individual approach. The result is transformers that meet the most stringent standards, fulfil their purpose efficiently and operate reliably and for the long term.

Interested in the highest possible efficiency transformer for your project? We will be happy to advise you, contact us.