Transformer breakdown: what do thermal classes mean and how do they affect performance

Transformers provide power transmission and distribution between different voltage levels. Their reliability and longevity depend not only on the design and type of core or winding used, but also on their ability to withstand the heat generated during operation. In the following sections, we will therefore look at the division of transformers according to thermal classes.

Thermal classes of transformers

The thermal class of the transformer represents the maximum operating temperature of the insulating material at which the equipment can operate safely without risk of damage. This parameter is defined by international standards and is a key element in determining the lifetime and reliability of the equipment.

Insulating materials have different heat resistance. Therefore, the thermal class of the transformer is directly related to the type of materials used for winding and core insulation:

- The higher thermal class allows the transformer to operate at higher temperatures, which can be advantageous in higher load applications or with frequent load fluctuations.

- A lower thermal class, on the other hand, means that the transformer operates at lower temperatures and its lifetime may be shorter under the same operating conditions.

Division of transformers by thermal class

According to international standards, transformers are classified into several thermal classes, which determine the maximum permissible operating temperature of their insulating materials. The most common classes are:

- Thermal class A ( maximum operating temperature 105 °C): mainly used in oil-immersed transformer types. These are materials with lower heat resistance, suitable for applications where less heating is expected.

- Thermal class B ( maximum operating temperature 130 °C): commonly used in industrial equipment and network switchgear. Provides a balanced combination of durability and resistance to thermal loads.

- Thermal class F ( maximum operating temperature 155 °C): used in dry or epoxy transformers with higher loads or where larger thermal peaks occur. It increases the resistance of the equipment and extends its lifetime in heavy duty applications.

- Thermal Class H ( maximum operating temperature 180 °C): designed for special transformers or applications with extreme thermal loads. Guarantees maximum safety and long service life even at very high operating temperatures.

Types of transformers and their thermal specifications

Transformers can be divided into several main types according to design, cooling method and purpose. For each of these, the thermal class is a key parameter influencing performance, safety and lifetime:

- Dry transformers: They use air or other gases to cool the windings. These transformers are most commonly manufactured in thermal class F, but also occur in class H. They are recommended for areas with high safety requirements, such as schools, hospitals, offices, and are also suitable for industrial applications due to their higher durability.

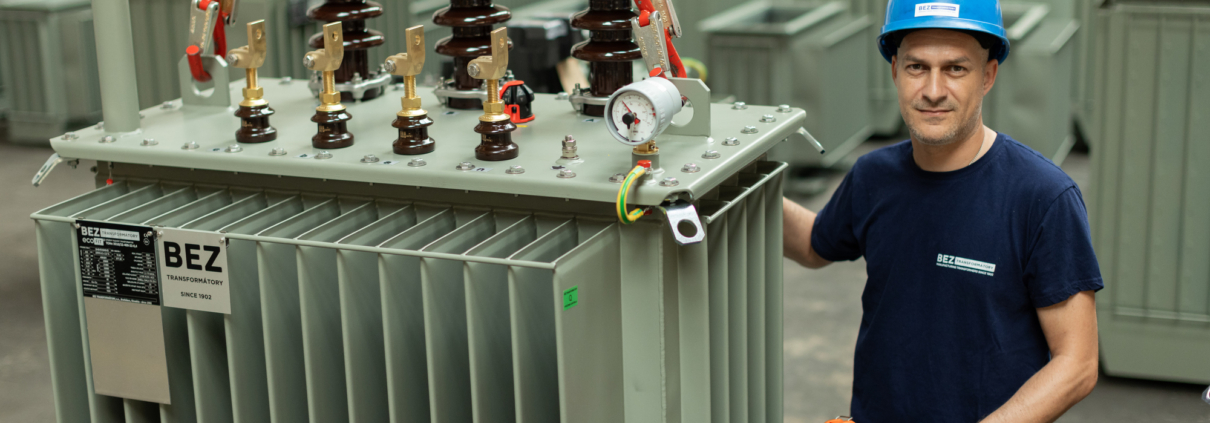

- Oil TransformersA: They use transformer oil as a refrigerant and insulating material. The thermal class is normally A or B. They are ideal for distribution networks. The oil also serves as an insulating material, which increases the safety and life of the transformer.

- Special transformers: They are used by critical applications, high power or industrial equipment. Thermal class A to H, often with special cooling systems (e.g. oil circulating or forced cooling). They are used where maximum reliability and minimized downtime are essential.

- Transformers for RenewablesA: Designed for solar, wind and other renewable energy sources. They often combine dry or oil-immersed construction with thermal class A to F depending on power rating and load intensity. They have to cope with power fluctuations and adapt to intermittent renewable energy generation. Intelligent temperature control systems help prevent overheating and optimize transformer life.

Effect of thermal class on performance and safety

The thermal class of the transformer has a direct impact on its operating performance, service life and safety. A higher thermal class allows the transformer to operate at higher loads without the risk of overheating. Overloading below the thermal capacity, on the other hand, can lead to increased losses and reduced efficiency. It is the optimally selected thermal class that allows the energy to be distributed efficiently even under fluctuating loads.

Transformer insulation materials degrade faster at high temperatures, so the closer the operating temperature is to the maximum thermal class, the faster the insulation aging occurs. Proper selection of the thermal class therefore extends the life of the equipment. The thermal class also determines the maximum safe operating temperature, thus protecting the transformer from overheating and possible failures. An improperly oversized transformer can cause a risk of fire or grid failures.

Only transformers with a suitable thermal class can operate stably under different operating conditions.

Practical recommendations from professionals

When selecting, consider the type of transformer, its design, installation location, expected operating load and specific conditions such as industrial environment or integration with renewable energy sources. When planning and upgrading electrical networks, select transformers not only according to power and winding type, but also according to thermal specifications. Taking thermal classes into account helps to prevent overheating, outages and faults, thereby improving the safety and reliability of the entire system.